Calcium Carbonate for Ceramics

Calcium Carbonate for Ceramics Specification

- Density

- 2.7 Gram per cubic centimeter(g/cm3)

- Form

- Fine Powder

- Purity(%)

- 96-99%

- Melting Point

- 1339 C

- Surface Finish

- Smooth

- Hardness (%)

- 3 Mohs

- Usage & Applications

- Used as flux in ceramics, in tiles, sanitary ware, glazes and frits.

- Chemical Composition

- Calcium Carbonate (CaCO3)

- Water Absorption

- Very Low

- Application

- Used in the manufacture of ceramics, glass, cement, and as a filler material

- Product Type

- Ceramic Raw Material

- Types of Refractories

- Basic Refractory

- Shape

- Powder

- Porosity

- Low

- Dimensional Stability

- Excellent

- Strength

- High mechanical strength

- Specific Gravity

- 2.7

- Thermal Conductivity

- Low

- Color

- White

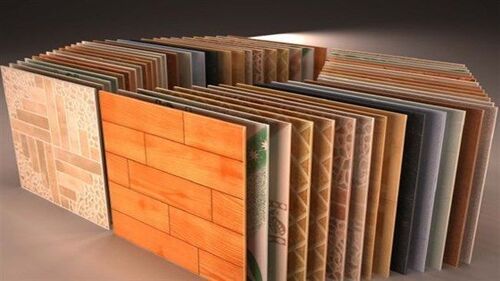

About Calcium Carbonate for Ceramics

Calcium Carbonate for Ceramics Calcium carbonate is another main component in the production of ceramics. Calcium carbonate is an economical source of calcium oxide, which is needed as a melting agent at high temperatures, improves the mechanical and chemical strength of the glass body and reduces shrinkage from firing. Calcium Carbonate is the main source of calcium in glazes and also a flux at high temperatures. Contributes hardness and durability and in large quantities produces a matt effect. It can enhance the finish of salt glaze ware by developing a thicker finish. Shivish Microns LLP provide wide range of calcium carbonate for ceramic different grads, with a very convenient solution for targets and cost models.Exceptional Whiteness and Purity

This calcium carbonate boasts a minimum whiteness of 96% and purity levels reaching up to 99%, resulting in a visually superior and reliable product for ceramic and related industries. The low moisture (maximum 0.2%) ensures stability and optimum quality, enhancing end-product aesthetics and performance.

Versatile Particle Sizes and Applications

Available in particle sizes from 150 mesh to as fine as 2 micron, this powder adapts perfectly to a range of processes. It is used as a flux in ceramics, tiles, sanitary ware, glazes, and frits, as well as in glass and cement production, making it a staple for manufacturers and traders worldwide.

Engineered for Performance

With its high mechanical strength, low thermal conductivity, and superior dimensional stability, this calcium carbonate delivers exceptional durability and performance. Its low oil absorption and water absorption characteristics further ensure minimal defects and a smooth surface finish in final products.

FAQ's of Calcium Carbonate for Ceramics:

Q: How is calcium carbonate used in ceramic manufacturing?

A: Calcium carbonate acts as a flux in the production of ceramics, tiles, sanitary ware, glazes, and frits. It aids in controlling the melting process and enhances mechanical strength, resulting in smoother surfaces and more durable products.Q: What are the benefits of its high whiteness and low moisture content?

A: High whiteness guarantees a premium appearance and consistency, while low moisture content (max 0.2%) minimizes processing issues, ensuring product stability and ideal surface finish in ceramics and related applications.Q: When should manufacturers choose fine particle sizes for calcium carbonate?

A: Fine particle sizes, such as 2 micron, are preferred when a smooth surface finish and uniform dispersion are desired, notably in glazes, frits, and high-quality tiles that require superior aesthetics and strength.Q: Where is this calcium carbonate primarily sourced and exported from?

A: This grade of calcium carbonate is manufactured and exported from India and is accessible through suppliers, traders, and exporters catering to worldwide markets.Q: What is the process to ensure its dimensional stability and mechanical strength?

A: Carefully controlled production ensures the powder maintains excellent dimensional stability and high mechanical strength, with strict adherence to purity and controlled bulk density, resulting in reliable performance in demanding ceramic applications.Q: How does low oil and water absorption benefit ceramic products?

A: Low oil and water absorption properties reduce the risk of surface defects and improve the finished product's durability, making this calcium carbonate particularly suited for applications like tiles and sanitary ware where surface quality is critical.Q: What are the advantages of its low thermal conductivity and basic refractory nature?

A: Low thermal conductivity combined with basic refractory qualities allow the material to withstand high temperatures during firing, lowering energy costs and enhancing product longevity in ceramic and glass manufacturing.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email